Obviously the next step is to bolt the valve cover back on. There are a ton of gaskets that need to be replaced, unfortunately they aren't cheap.

Clymer manual is a bit vague on how to seal the valve cover gasket in. It says to use sealer but does not say where or how much. My rule of thumb with sealer is to use as little as possible to get the job done. So here are the points on the valve cover where I applied a very small dab of sealer:

Next step is to press fit the valve cover gasket. The gasket can go in two ways and it's difficult to tell which is correct. Neither the Clymer manual nor the service manual are any help in this regard. Fortunately the valve cover is not completely symmetrical. On careful inspection there is a small angular bend at the front, and the gasket also has this bend. The gasket has a rubber tab which is confusing, it does not cover the metal tab on the valve cover.

In my case I also used some Ultra Black RTV sealer to plug the hole that the reputable shop in SF made when they tried to pry it off.

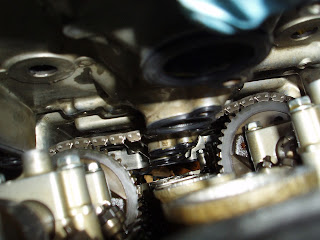

Next, slide the valve cover back in, while carefully not snagging any of the round gaskets on the cam chain. This took me a couple of tries. It is very important that the round gaskets stay in place.

Per instructions in the manual, put a dab of sealer on the underside of each of the semicircle tabs on the valve cover gasket. I do not believe this is strictly necessary but I always do it.

Next is the slow and painstaking process of bolting down the valve cover. Replace the banjo bolt washers and disc-shaped gaskets, clean all the bolts thoroughly with solvent and dry them.

Install the banjo bolts and finger tighten.

Next install the shoulder (gasketless) bolts and valve cover bolts finger tight. Then tighten all bolts a quarter turn in criss-cross pattern in the following order:

- Inner banjo bolts

- Outer banjo bolts

- Shoulder bolts

- Inner valve cover bolts

- Outer valve cover bolts

Repeat the quarter-turn tightening sequence by hand, over and over, until all bolts feel just a little bit snug. It may take 6 - 8 iterations.

After all bolts are slightly snug (slight resistance to turning) it is time to break out a good-quality inch-pounds torque wrench. Set to 40 in-lbs and repeat the quarter-turn tightening sequence until all bolts are at 40. Then set it to 60 and repeat. Finally set it to 77 in-lbs and tighten all bolts in sequence until they are at 77. Some bolts will need to be hand-tightened as there is not enough clearance for a torque wrench. Make sure they feel like they are similarly tightened, or slightly less tight, as the bolts measured by the torque wrench.

Note that the manual will state 10 ft-lbs for valve cover bolts and 12 for the banjo bolts. IMO that is excessive. The goal here is to maintain oil pressure and prevent leaks, and 77 in-lbs is enough. [Edit: after a week the banjo bolts were leaking a tiny bit, so I tightened them to 83 in-lbs--see addendum.] The added torque will simply make the valve cover more difficult to remove next time and put undue stress on delicate threads in the cam caps and cylinder head. 77 in-lbs is plenty.

Next put a new o-ring in each of the oil hoses and torque them down. The manual calls for 88 in-lbs but again, 77 is plenty.

Next step is to reattach the breather. There is a tab on the gasket to orient it properly.

There is no torque spec associated with the breather. Slightly snug is all.

Reattach the PAIR valve and hoses. It's easier to put the hoses on the valve before bolting the valve onto the frame.

Finally it's a good idea to clean the air filter by blowing compressed air into the engine side, after valve service. Unscrew the 2 air box screws, remove the air filter, and blow compressed air into the back side of it. Replace at 32k miles or if it's filthy.

After the valve clearances are within spec it's a good idea to synchronize the carburetors. I will detail this in a separate write-up, suffice to say it requires a carb-tune manometer tool, at least one fan, and a lawn mower gas tank. Carbs 1 -3 should be adjusted to match carburetor #4 at 1750 RPM. In practice this is nearly impossible so good enough is good enough.

No comments:

Post a Comment